COMPANY SERVICES

SMT

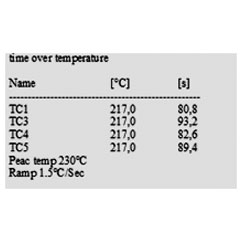

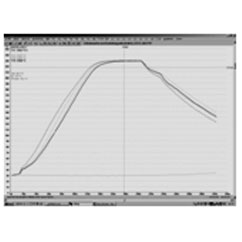

The three automated SMT lines at Tzemach Moshe Technologies are the most technologically advanced. The I-PULSE ,DEC 'smt placement lines are designed to provide an efficient and immediate response to customers at the development stages, and high-mix companies. Additionally, the advanced lines can also provide a solution for serial production that requires large-volume production. In all types of works,our clients enjoy professional and relevant service for every project whatsoever.

- FP

- POP CHIP ON CHIP Components

- 01-005

- Micro BGA

- QFP/QFN

- LGA

- BGA Connector

Tzemach Moshe Inc. is also able to provide solutions for special components. The more complex and smaller the components are, the greater is the observation of the smallest details. From the design of the stencil, through the use of the correct solder paste and down to the placement using the SMT machines.

Tzemach Moshe Technologies provides a solution for all types of circuits , RF circuits, flexible circuits, military circuits…. Tzemach Moshe Technologies operates an engineering department that guides the customer through the product design sage, starting from the card preparation, and all the way to providing a complete solution for all stages of production and the production of a product portfolio. Tzemach Moshe Inc. is in contact with the leading technologists in order to provide a solution for every problem.